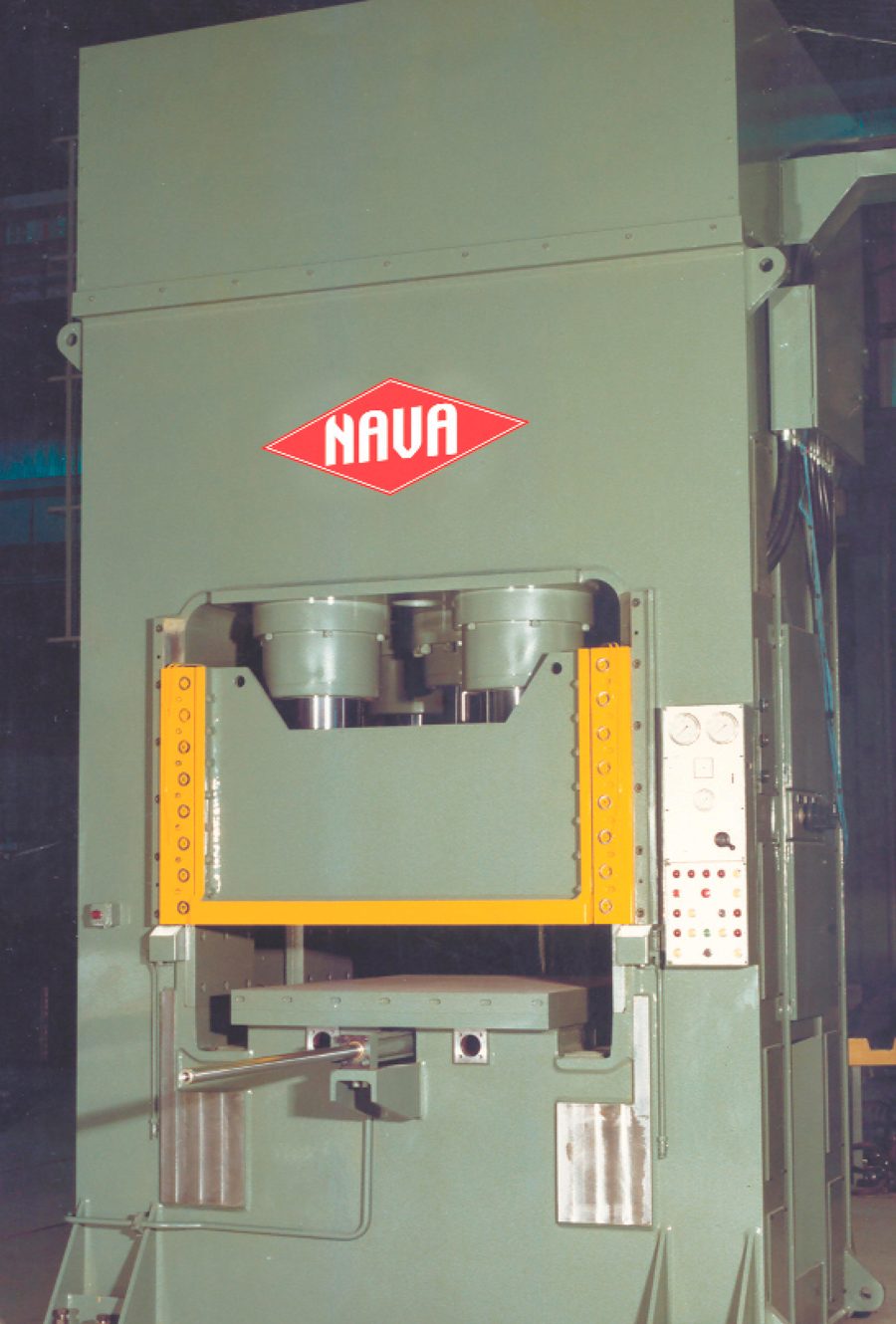

We have produced numerous presses for some of the industry leaders, introducing a significant change in the compacting process, precisely by moving from an almost manual and “not numerically controlled” compression process (carried out with screw/nut press systems) to a numerically controlled system in which the pressure exerted by the press ensures parallelism between the two end surfaces and a force that is constantly controlled and displayed at every stage of its advancement.

Our presses make it possible to have an automated tracking of the cycle performed associated with the serial number of the workpieces.

Considerable attention has been paid to operator safety and optimisation of work cycles (which have been made faster thanks to the introduction of innovative technology using special self-propelled structures).