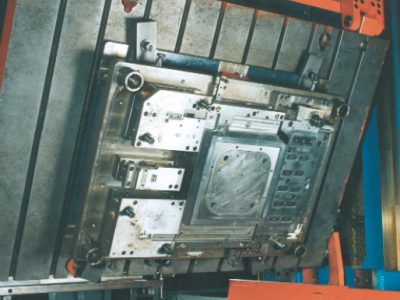

The hydraulic presses for mould testing are designed and manufactured to set-up the moulds made so that they can be qualified and be immediately productive when installed on the production presses.

To obtain the best performance from the moulding lines, it is useful to check the moulds thoroughly using a specially designed press, which allows finishing operations on both internal faces of the mould without compromising the centring of the two halves.